Description

Mission Sand Master Series 4x3x13 Centrifugal Pump Sandpump 20250420

Each pump contains the finest materials, engineering and craftsmanship available in the industry. Described are like features of these pump lines and unique features are described on the following pages. Utilizes unique design features developed for slurries. Three major differences from most pump designs include the concentric casing, wider impellers and increased recirculation areas. Each feature contributes to reducing wear when handling abrasive fluids.

Thicker, Stronger, Concentric Casing

All of the pumps feature a concentric casing. This casing averages 37% thicker than conventional pump casings, and up to 50% thicker for the larger, mud pumping models. They are pressure rated at 1.5 times the flange rating and are designed with a 1/8″ erosion allowance.

The concentric style casing has proven to offer the greatest pump life and reduced downtime. The walls of a concentric style casing are an equal distance from the impeller throughout the impeller circumference, which results in a smooth flow pattern. A volute style casing has a cutwater point that disturbs the fluid flow pattern creating an eddy. The concentric casing eliminates vibration, turbulence and aeration that is caused by the cutwater point in conventional volute pumps. It also reduces the high bearing loads and shaft deflection even at near shutoff flows.

Wider Impeller, Increased Re-circulation Area

National Oilwell Varco’s impeller design has wider vanes at the tip which decreases the velocity of the fluid exiting the impeller. This eliminates the abrasive jetting effect that is present with narrow impellers. The distance between the impeller tip and the casing is

greater resulting in an increased re-circulation area.

Lower velocity rates and increased re-circulation areas allow the exiting fluid to blend with the re-circulating fluid reducing turbulence and wear. The entrance shape of the impeller vanes is more tangential to the circumference of the suction creating a smoother flow

pattern. Smooth flow is crucial when handling abrasive fluids.

Heavy-Duty Shaft

The shaft is much larger in diameter than conventional pump shafts for heavy-duty performance, minimum deflection and increased operating life of the seal or packing. With a 2-1/2” diameter at the seal area and 3” diameter between the bearings these pumps can be direct connected or belt driven.

The shaft area under the packing is protected by a replaceable, hook type sleeve with one end free to expand with temperature variation. This sleeve can be replaced in the field without shaft removal.

Highest Quality Bearings

Advanced front and rear bearing design reduces both radial and thrust loads. The outboard bearing is a duplex set of angular contact bearings with high thrust load capabilities and zero endplay. This bearing set features 24 large balls that are preloaded so that each bearing carries an equal load.

National Oilwell Varco utilizes an inboard bearing that is a single row roller bearing with high radial load capabilities.

This bearing was selected to replace the previously utilized double row bearing due to its engineered bearing life of over 2.2 times the L10 life of previously utilized double row ball bearings.

Bearing Lubrication Options

Oil or grease lubrication is available. Grease lubrication is the factory standard. Oil lubrication is recommended for pump speeds in excess of 2400 RPM. Oil lubricated pumps must be maintained in a horizontal level position.

Mechanical Seal Options

A type I single tungsten carbide vs. tungsten carbide mechanical seal is standard. Tungsten carbide has proven itself as a highly abrasive resistant material with a Ph range of 7 to 14, depending on chemical composition.

For applications with a lower Ph level the silicon carbide vs. silicon carbide mechanical seal is recommended with its Ph range from 0-14, depending on chemical composition. Both mechanical seals are lubricated by the fluid being transferred and require the pump to remain primed during operation.

When the pump is subject to high temperature fluids, oil base muds with low aniline points, running dry or extremely abrasive fluids, the Olympia™ cartridge type double mechanical seal is the solution. Utilizing a barrier fluid between the two seals ensures the seal faces remain lubricated even when the pump is run dry. The fluid being transferred has virtually no effect on the seal since the barrier fluid is in contact with the seal faces.

Custom mechanical seal options can be provided for specific applications.

Versatile Stuffing Box

An easily removable stuffing box allows these pumps to be customized to meet customer needs. The different options available are stuffing boxes to accommodate:

• Shaft packing

• Single mechanical seal

• Olympia™ Double mechanical seal with barrier fluid

• Specialized mechanical seals

The packed box has a tapped opening to the lantern ring to allow grease lubrication or a flush line to be attached.

Dual stuffing box bolts are positioned 180 degrees apart to hold the stuffing box in position during casing removal.

When only one stuffing box bolt is used the stuffing box remains in position on one side while the other side moves with the casing, causing the casing to bind and make removal difficult.

Casing Jack Bolts

Casing jack bolts are an added feature to the Magnum and 2500 Supreme pump lines. Jack bolts allow the casing to be mechanically removed eliminating the need for pry bars or striking the casing during maintenance.

This feature simplifies maintenance and eliminates damage to the casing and pedestal during disassembly.

Solid Frame Base

The solid frame base strengthens the pump and eliminates broken feet that occur with pumps equipped with a split base.

Fluid End Materials

Various fluid end materials are available that allow these pumps to be utilized for a variety of applications. Standard pumps are supplied with a hard iron fluid end but can be upgraded to stainless steel, aluminum bronze,

Magnachrome™, or Supreme Hard. These materials are available for select sizes and can be purchased as a complete or fitted fluid end.

Magnachome material is a proprietary material exclusive to National Oilwell Varco and is formulated specifically for its high abrasion resistant qualities. Magnachrome is approximately 3 times harder than Hard Iron. The Supreme Hard material is approximately 2 times harder than Hard Iron.

Technical Support and Parts Availability

With locations and distributors throughout the world, National Oilwell Varco ensures our customers can obtain technical assistance and pump parts in a timely manner. Engineering support, literature and electronic manuals are available to help properly size and service equipment.

Superior Packaging and Labeling

All parts are properly packaged to protect the equipment during shipping. The material is clearly marked to ensure our customers are getting OEM manufactured parts and allow packers and service hands to confirm they have the correct equipment without having to open the packaging and expose the equipment to external elements.

Magnum and 2500 Supreme

National Oilwell Varco is dedicated to providing a full line of products to meet the needs of our customers. Realizing customer needs and priorities may differ, National Oilwell Varco provides two separate pump lines with like operating and dimensional characteristics. Following are the unique features of the Magnum and 2500 Supreme.

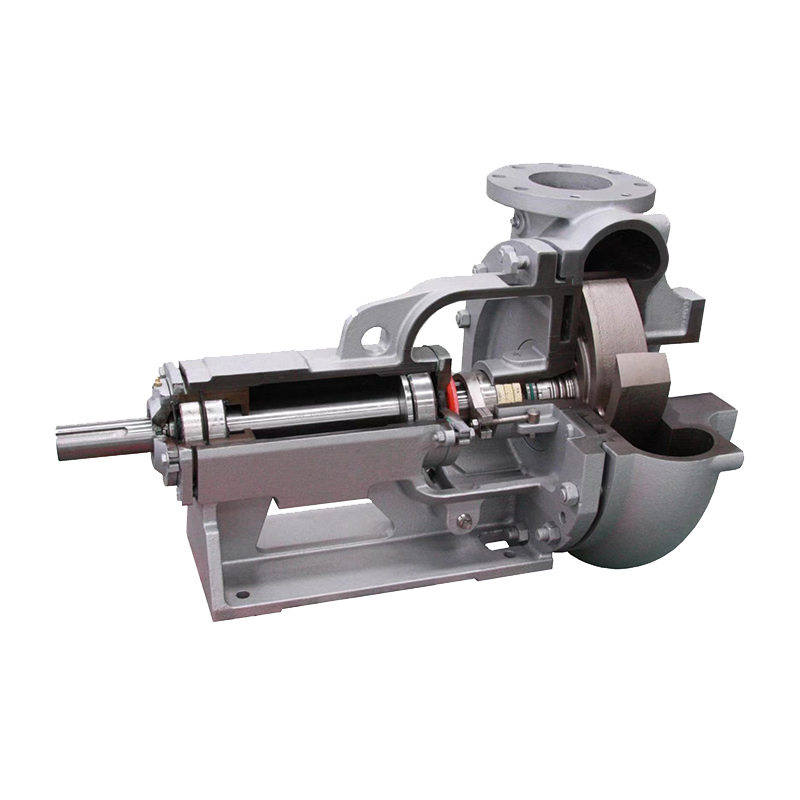

SANDMASTER PUMPS

The compact and adaptable Sandmaster centrifugal pump includes virtually all of the features of the Magnum I. Sandmasters are more compact in design and can be adapted for hydraulic motor drive. These features make Sandmaster pumps ideal for use in applications such as oilfield frac trucks as well as blending and pump charging for water well drilling applications.

All parts for these pumps are identical to the Magnum except for the frame and shaft. The frame and shaft have been shortened 4” to reduce the length of the pump. When space is a premium and prime mover options are limited, the Sandmaster is the pump of choice.

| Sandmaster Centrifugal Pump Parts List | |||||

| Item | Qty | Catalog Number | Part # | Description | Material |

| 1* | 1 | See Below | See Below | Casing | Hard Iron |

| 1A | 1 | 10399-46-1 | 648403012 | Gasket, Casing | Vellumoid |

| 1B | 12 | 3932-61 | 648402014 | Nut, Casing | Stl |

| 1C | 12 | 3862-76 | 648401115 | Stud, Casing | Stl |

| 1D | 1 | 8505-04-01 | 86485503 | Plug, Casing Drain | Stl |

| 1E | 1 | 8505-04-01 | 646400507 | Plug, Flush Line | Iron |

| 2* | 1 | See Below | See Below | Impeller | Hard Iron |

| 2A | 1 | 19110-72 | 648405082 | Seal, Impeller | Viton |

| 2B | 1 | 7300239 | Washer, Impeller | Stl | |

| 2C | 1 | 7415648 | Bolt, Impeller Lock | Stl | |

| 3*# | 1 | 22223-01-30 | 641116157 | Stuffing box, Mech. Seal | Hard Iron |

| 3*& | 1 | 20614-01-30 | 643365042 | Stuffing Box, Packed | Hard Iron |

| 3A | 2 | 3861-117 | 648401016 | Bolt, Stuffing box | Stl |

| 3B& | 1 | 19368-01 | 601499403 | Grease Fitting | Stl |

| 4 | 1 | 20622A | 641103338 | Gland Assy., Packing | Bronze |

| 5A# | 1 | 22451-1 | 648414308 | Seal, Mechanical | Tungsten Carbide |

| 5A~ | 1 | 25014-04M-B | 661007005 | Packing, Shaft | Graphite/Acrylic |

| 6 | 2 | B3701A | 601102494 | Bolt Assy, Gland | Stl |

| 7 | 1 | 20612-02-33 | 646490557 | Shaft | AISI 4140 |

| 7A# | 1 | 20943-21 | 641102182 | Sleeve, Shaft (M.S. Pump) | 416SS |

| 7A& | 1 | 20613-21G-7A | 641102181 | Sleeve, Shaft (Pack Pump) | 416SS/Ceramic |

| 7B | 1 | 4372-5-21 | 601212392 | Key, Shaft | 416ss |

| 7C | 1 | 23444-01-72 | 648415156 | Seal, Shaft Sleeve | Viton |

| 8 | 1 | 22210-1A | 641116108 | Deflector Assembly | Bronze |

| 9 | 1 | 20618-12-1 | 644302499 | Frame, Grease Lubricated | Cast Iron |

| 9A! | 1 | 8505-05 | 601474737 | Plug, Oil Drain | Iron |

| 9B! | 1 | 18471 | 648403608 | Plug, Oil Fill | Iron |

| 9C | 1 | 8505-05 | 601474737 | Plug, Frame Drain | Iron |

| 9D | 1 | 8267-01 | 601473689 | Breather | Stl |

| 9E | 1 | 8478-3 | 601174584 | Oiler Assembly | |

| 9F! | 1 | A 662014131 | 662014131 | Dip Stick | Stl |

| 9G | 3 | 2538-1H | Bolt, Casing Jack | Stl | |

| 10A | 1 | 20626 | 644303109 | Cover, Inboard Bearing | Iron |

| 10B | 1 | 20625 | 648408706 | Gasket, I.B. Brg. Cover | Vegetable Fiber |

| 10C | 1 | 20619-01 | 648408300 | Oil Seal, I.B. Brg. Cover | Buna-n |

| 10D | 2 | 3861-1 | 601407505 | Bolt, I.B. Brg. Cover | Stl |

| 10E | 2 | 3932-2 | 601408560 | Nut, I.B. Brg. Cover | Stl |

| 10F | 1 | 20620-01 | 648408409 | Exclusion Seal, I.B. Brg. Cvr. | Buna-n |

| 10G | 1 | 21641-01 | 661010033 | Grease Fitting | Stl |

| 10H | 1 | 648411908 | Grease Fitting | Stl | |

| 11 | 1 | N/A | 661009010 | Bearing, Inboard | Vendor |

| 12 | 1 | 20624-01-01 | 644308504 | Housing, O.B. Bearing | Iron |

| 12A | 1 | 7496-253 | 648402295 | Seal, O.B. Brg Housing | Buna-n |

| 12B | 4 | 3861-138 | 648401057 | Bolts, O.B. Brg. Housing | Stl |

| 12C | 2 | 3932-62 | 658404702 | Nut, O.B. Brg. Housing Jam | Stl |

| 13 | 1 | 20617-01-01 | 641103296 | Cover, O.B. Bearing | Iron |

| 13A | 1 | Grease Zerk, O.B. Brg. Cvr. | Stl | ||

| 13B | 1 | 7496-26 | 072200017 | O-ring, O.B. Bearing Cover | Buna-n |

| 13C | 1 | 20619-02 | 648408359 | Oil Seal, O.B. Brg. Cover | Buna-n |

| 13D | 2 | 3861-139 | 648401081 | Bolt, O.B. Brg. Cover | Stl |

| 14 | 2 | N/A | 648408201 | Bearing, O.B. (2 Req’d) | Vendor |

| 14A | 1 | 6124-4 | 648402105 | Lockwasher, O.B. Bearing | Stl |

| 14B | 1 | 6123-4 | 648402055 | Lucknut, O.B. Bearing | Stl |

| Casing-Includes Studs, Nuts and Gasket | |||||

| 1* | 1 | 19203-01-30A | 641101753 | Casing, 3x2x13 | Hard Iron |

| 1* | 1 | 19205-01-30A | 641101902 | Casing, 4x3x13 | Hard Iron |

| 1* | 1 | 19222-01-30A | 641102058 | Casing, 5x4x14 | Hard Iron |

| 1* | 1 | 19122-01-30A | 641101456 | Casing, 6x5x11 | Hard Iron |

| 1* | 1 | 19123-01-30A | 641101605 | Casing, 6x5x14 | Hard Iron |

| 1* | 1 | 19763-01-30A | 641102157 | Casing, 8x6x11 | Hard Iron |

| 1* | 1 | 19117-01-30A | 641101308 | Casing, 8x6x14 | Hard Iron |

| 1* | 1 | 20937-01-30A | 641102322 | Casing, 10x8x14 | Hard Iron |

| Impellers | |||||

| 2* | 1 | 19204-XX-30 | Varies | Impeller, 3x2x13 | Hard Iron |

| 2* | 1 | 19206-XX-30 | Varies | Impeller, 4x3x13 | Hard Iron |

| 2* | 1 | 19224-XX-30 | Varies | Impeller, 5x4x14 | Hard Iron |

| 2* | 1 | 19121-XX-30 | Varies | Impeller, 6x5x11 | Hard Iron |

| 2* | 1 | 19121-XX-30 | Varies | Impeller, 6x5x14 | Hard Iron |

| 2* | 1 | 19121-XX-30 | Varies | Impeller, 8x6x11 | Hard Iron |

| 2* | 1 | 19116-A0-30 | Varies | Impeller, 8x6x14 | Hard Iron |

| 2* | 1 | 21867-XX-30 | Varies | Impeller, 10x8x14 | Hard Iron |

| XX – Impeller Code – First X equals diameter of impeller in inches minus 4. Therefore 10″ = 6, 9″= 5,8″=4, etc… 14″ use letter A. Second X equals fractional data in 1/8’s. Therefore 1/8″ = 1, 1/4″ = 2, 1/2″ = 4, etc…Thus a 10.5″ impeller is coded as 64, a 12″ impeller is coded as 80, a 13.25″ impeller is coded as 92 etc. Notes: * – Casings, Impellers and Stuffing Boxes are also available as Stainless Steel, Aluminum Bronze or Magnachrome – See local dealer for Part Numbers. # – Used for pumps equipped with mechanical seal only. & – Used for pumps equipped with packing only. ! – Used for oil lubricated pumps only. ~ – Packing available in various materials – standard material shown |

|||||